- Welcome to Hunan Shiney Steel Co., Ltd.

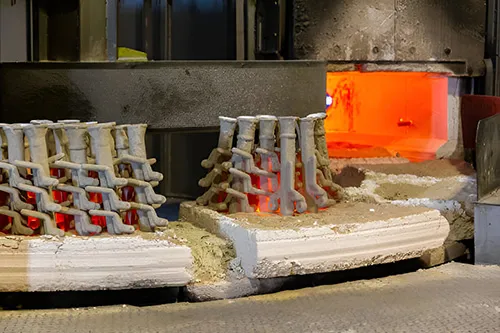

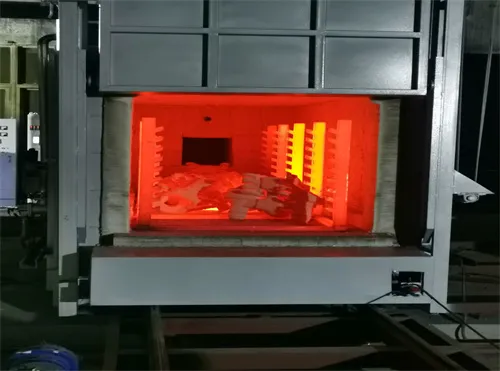

With over two decades of expertise in producing high-quality metal parts, Shiney Steel has firmly established itself as a leading provider in the casting and forging industry. Based in Changsha, Hunan, Shiney Steel operates two specialized subsidiary factories that deliver a range of services, including Investment Casting, Sand Casting, Die Casting, Forging, and Precision Machining.

At the heart of Shiney Steel' commitment to quality is its dedication to maintaining the highest industry standards. The company is ISO9001:2015 certified, ensuring that all products meet the rigorous demands of OEM and ODM clients globally. Whether for automotive, aerospace, or energy sectors, Shiney Steel produces parts that meet the toughest specifications, offering superior finishes, high accuracy, and exceptional designs.

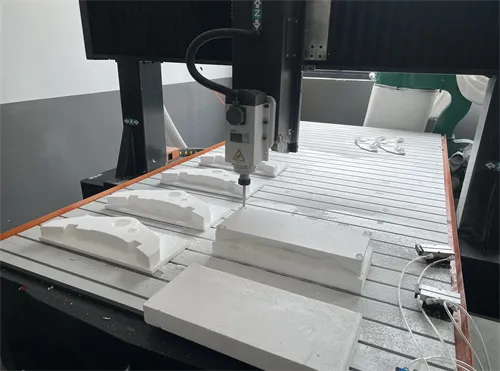

As a trusted partner for advanced casting and forging solutions, Shiney Steel blends cutting-edge technologies with traditional craftsmanship. Their state-of-the-art CNC machining capabilities, including VMC machinery, gear cutting, and profile grinding, ensure that even the most complex machining needs are met with precision and efficiency.

Recognized worldwide for its reliability, Shiney Steel is the preferred choice for OEMs and companies looking for custom-forged parts. With an unwavering commitment to excellence, Shiney Steel continues to be at the forefront of the casting and forging industry, providing innovative solutions and delivering unmatched customer satisfaction.

Let Shiney Steel be your partner in advancing your metal parts needs—where quality meets precision.

We continuously invest in advanced equipment and technology, including modern Machining Centres (HMCs, VMCs, VTLs) and Special Purpose Machines, to deliver efficient and cost-effective services.

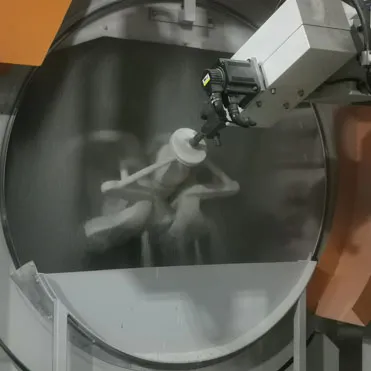

Robotic automation and real-time software give us complete visibility into production, planning, and data tracking.

Our expertise in handling various alloys allows us to suggest process improvements without compromising on quality or performance.

Beyond supplying cast and forged components, we also provide full and sub-assembly services for major OEMs.

Our experienced team utilizes modern welding techniques—fusion welding, pressure welding, brazing, soldering—ensuring strong, reliable assemblies while saving time and cost.

Flexible work cells and cross-trained staff enable us to handle diverse fulfillment models efficiently.

Our engineering team supports customers from the early design phase through prototyping to ensure products meet the required features and specifications.

We collaborate closely to solve material challenges and improve structural design.

Sample production with a variety of materials, dimensions, and specifications is available to suit different needs.

We offer a full range of treatments including heat treatment, normalizing, quenching, tempering, nitriding, carburizing, annealing, induction hardening, and more.

Surface finishes such as sandblasting, painting, electroplating (zinc, nickel, chrome), hot-dip galvanizing, and thermal spray metalizing are also available.

We regularly monitor Quality Key Performance Indicators to ensure all treatment processes deliver consistent, high-standard results.

The customer faced major issues with their previous aluminum casting process, including inconsistent quality, high rejection rates, long lead times, and elevated production costs. These problems made it difficult for them to meet market demand and stay competitive.

Shiney Steel collaborated closely with the customer’s technical team to deliver a tailored aluminum casting solution. Our approach included: