- Welcome to Hunan Shiney Steel Co., Ltd.

Investment casting is known as a precision casting process, which products complex and intricate metal parts with higher quality than sand casting process.

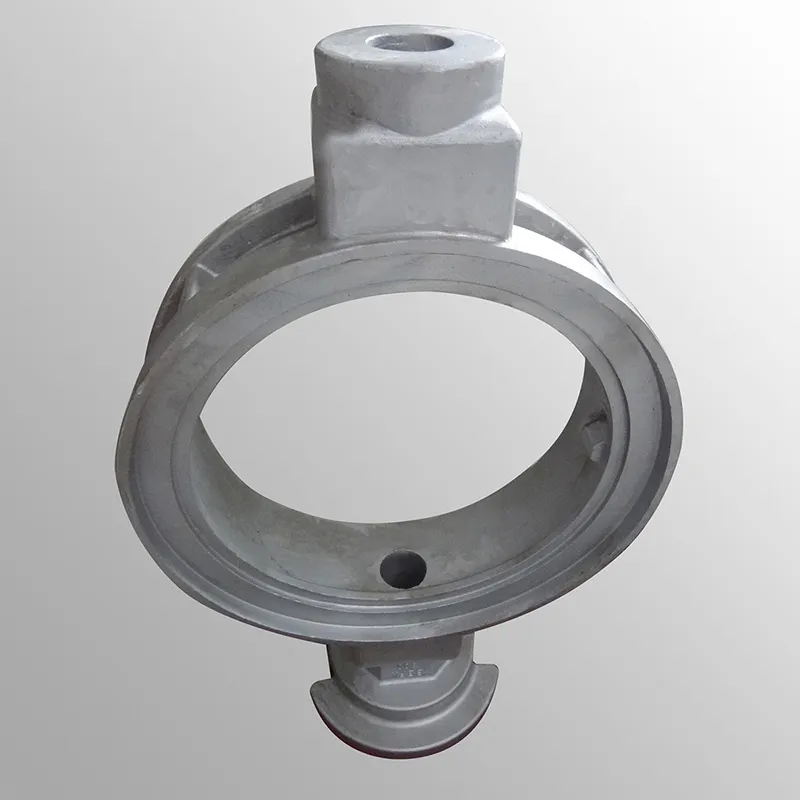

Lost wax investment castings using silica sol as a binder material can achieve dimensional tolerance grades of CT4 to CT7, in accordance with ISO 8062. Our fully integrated equipment and automated process controls ensure consistent, repeatable tolerances, with precision as tight as ± 0.1 mm. These lost wax castings can be produced in a wide range of sizes, from as small as 10 mm (length, width, and height) weighing just 0.01 kg, to as large as 1000 mm in length and up to 200 kg in weight.

Investment casting, also known as "lost wax casting," involves coating a wax pattern with several layers of refractory material. Once the coating hardens, the wax pattern is melted away to create a mold shell. Liquid metal is then poured into the mold, and after cooling, it solidifies to form the desired cast part.

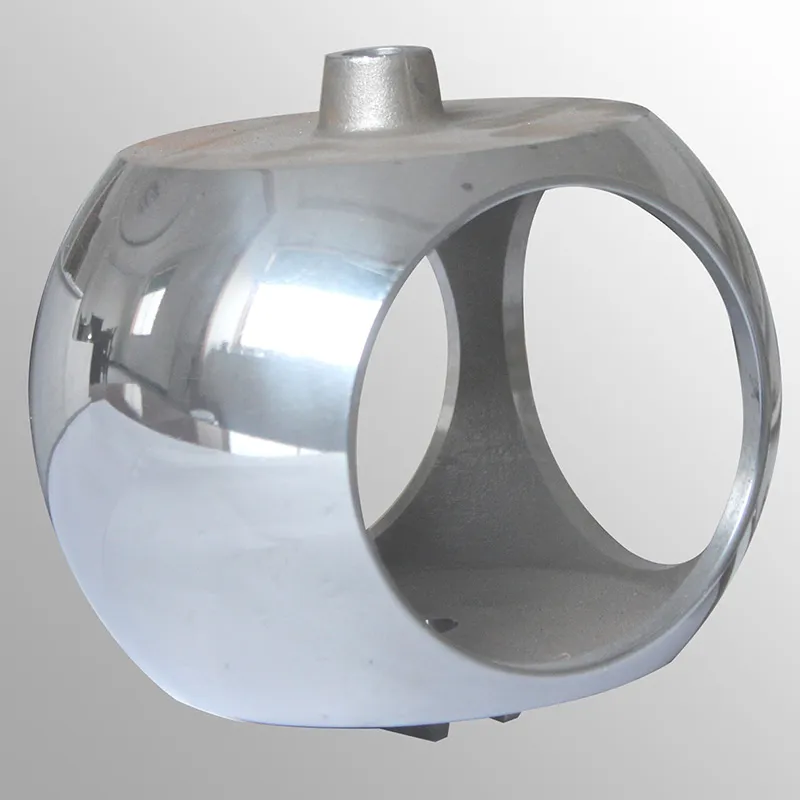

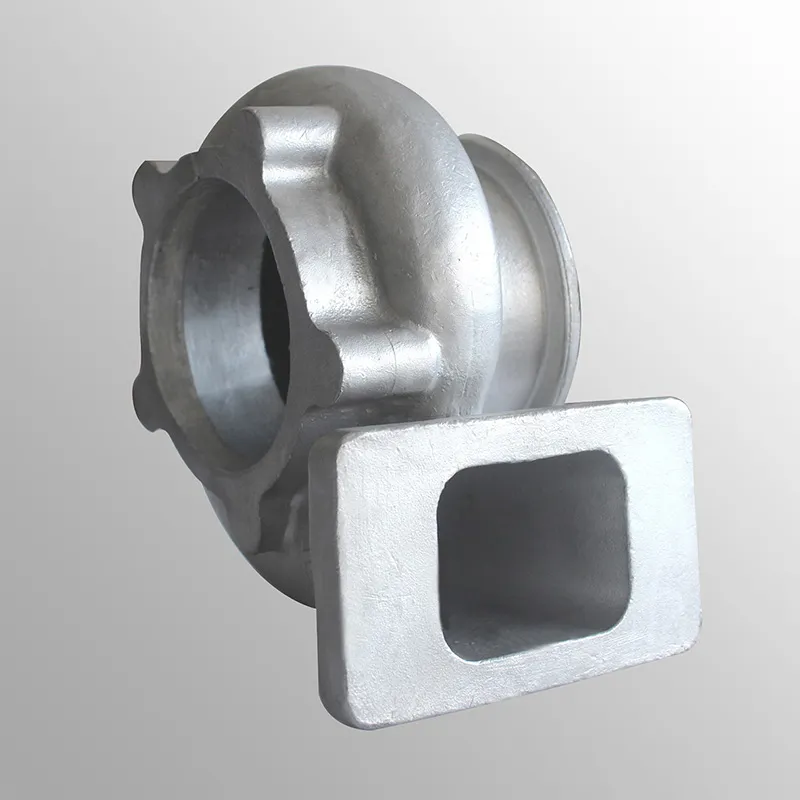

Due to its high dimensional accuracy and superior surface finish, investment casting is often referred to as "precision investment casting." This process can produce a wide range of alloys, including carbon steel, alloy steel, heat-resistant alloys, stainless steel, copper alloys, aluminum alloys, titanium alloys, and nickel-based alloys, among others.

The shapes of investment castings are typically complex. At Shiney Steel Foundry, we can cast holes with a minimum diameter of 0.5 mm, and the minimum wall thickness of our castings is 3 mm. In production, parts that would traditionally be made from multiple components can be combined into a single, integrated design. By modifying the part structure, we can directly cast it using the investment casting process, saving both production time and material costs, while improving the overall design.

Investment castings typically range in weight from 20g to 60kg. While larger castings are possible, producing them becomes more difficult, and in such cases, sand casting may be a more appropriate alternative.

With the latest investment casting technology, Shiney Steel brings extensive experience in customizing your metal parts, from design to production. By partnering with our foundry, you can enjoy several key benefits:

Outstanding Quality:

We’ve invested in advanced casting production equipment, including automatic wax injection machines and robotic arms, to enhance production efficiency. These automated processes significantly reduce errors caused by manual handling, ensuring more consistent and reliable quality. Additionally, our rigorous quality control procedures further guarantee that every part meets high standards.

Competitive Pricing:

Thanks to China’s cost advantages in labor and materials compared to investment casting companies in the US or Europe, we can offer highly competitive pricing on both mold costs and unit prices. As one of China’s leading investment casting manufacturers, we pass on these savings to you.

Fast Delivery:

Despite a continuous flow of orders, we maintain multiple production lines to keep production running smoothly, even during large production runs. This enables us to deliver your parts in as little as four weeks, ensuring timely service for your projects.