- Welcome to Hunan Shiney Steel Co., Ltd.

|

ALLOY NAME |

MECHANICAL PROPERTIES |

MATERIAL CHARACTERISTICS |

APPLICATION INDUSTRY |

EXAMPLE PART |

|

Austenitic - Corrosion Resistance (Higher Nickel) |

||||

|

304 stainless steel |

Tensile Strength: 515-690 MPa, |

Widely used, Ductility (low |

Food Processing, Kitchen |

Kitchen sinks, Process |

|

304L stainless steel |

Tensile Strength: 485-655 MPa, |

Ductility (lower carbon for |

Chemical, Oil & Gas |

Process equipment, Heat |

|

316 stainless steel |

Tensile Strength: 515-690 MPa, |

Excellent Corrosion Resistance |

Paper industry, Chemical |

Propellers, Medical |

|

316L stainless steel |

Tensile Strength: 485-655 MPa, |

Improved Weldability, Corrosion |

Marine, Chemical |

Marine components, |

|

201 stainless steel |

Tensile Strength: 620-795 MPa, |

Cost-Effective (lower nickel), |

Construction, Automotive |

Structural components, |

|

Duplex - High Strength, Duplex Structure |

||||

|

2205 stainless steel |

Tensile Strength: 620-800 MPa, |

Resistance to Stress and |

Oil & Gas, Chemical |

Pipes, Pressure vessels |

|

Martensitic - Heat Treatable, Moderate Corrosion |

||||

|

410 stainless steel |

Tensile Strength: 450-655 MPa, |

Moderate Corrosion Resistance, |

Aerospace, Firearms |

Aircraft components, |

|

PH - Precipitation-Hardened (By Ageing) |

||||

|

17-4ph |

Tensile Strength: 725-930 MPa, |

High Strength, Precipitation- |

Aerospace, Medical |

Aircraft landing gear, |

| Duplex Stainless | Nominal Composition | ||||||||||||

| Grade | C | Si | Mn | CR | Mo | Ni | Cu | Nb | V | Fe | W | Co | N |

| ASTM A995 J93372 ( 1B ) | 0.04 | 1 | 1 | 25.5 | 2 | 5.5 | 3 | 0.18 | |||||

| 10213 GX2CrNiMoN25-6-3-3 | 0.04 | 1 | 1 | 25.5 | 2 | 5.5 | 3 | ||||||

| ASTM A995 J93373 (1C ) | 0.03 | 1 | 1 | 25.5 | 3.5 | 6.5 | 1.5 | 0.25 | |||||

| 10213 GX2CrNiMoN26-7-4 | 0.03 | 1 | 1 | 25.5 | 3.5 | 6.5 | 1.5 | 0.25 | |||||

| ASTM A995 J93345 (2A ) | 0.08 | 1.5 | 1 | 24 | 4.75 | 10 | 0.2 | ||||||

| ASTM A995 J93371 (3A ) | 0.06 | 1 | 1 | 25.5 | 2 | 5 | 0.2 | ||||||

| ASTM A995 J92205 ( 4A ) | 0.03 | 1 | 1.5 | 22 | 3 | 5.5 | 1 | 0.2 | |||||

| 10213 GX2CrNiMoN22-5-3 | 0.03 | 1 | 1.5 | 22 | 3 | 5.5 | 1 | 0.2 | |||||

| ASTM A995 J93404 ( 5A ) | 0.03 | 1 | 1.5 | 25 | 4.5 | 7 | 0.2 | ||||||

| 10213 GX2CrNiMoN25-6-3 | 0.03 | 1 | 1.5 | 25 | 4.5 | 7 | 0.2 | ||||||

| ASTM A995 J93380 ( 6A ) | 0.03 | 1 | 1 | 25 | 3.5 | 7.5 | 0.75 | 0.75 | 0.25 | ||||

| Ferritic/Martensitic | Nominal Composition | ||||||||||||

| Grade | C | Si | Mn | CR | Mo | Ni | Cu | Nb | V | Fe | W | Co | N |

| ASTM A487 CA15 | 0.15 | 1.5 | 1 | 12.5 | 0.5 | 1 | |||||||

| ASTM A743 CA6N | 0.06 | 1 | 0.5 | 11.5 | 7 | ||||||||

| ASTM A487 CA6NM | 0.06 | 1 | 1 | 13 | 0.6 | 4 | |||||||

| ASTM A487 CB7CU-1 | 0.07 | 1 | 0.7 | 16 | 4 | 3.8 | 0.25 | ||||||

| ASTM A487 CB7CU-2 | 0.07 | 1 | 0.7 | 16 | 0.05 | 5 | 3.8 | 0.3 | |||||

| Austenitic Stainless | Nominal Composition | ||||||||||||

| Grade | C | Si | Mn | CR | Mo | Ni | Cu | Nb | V | Fe | W | Co | N |

| ASTM A351 CF3 | 0.03 | 2 | 1.5 | 19 | 0.5 | 10 | |||||||

| ASTM A351 CF3M | 0.03 | 1.5 | 1.5 | 18 | 2.5 | 11 | |||||||

| ASTM A351 CF3MN | 0.03 | 1.5 | 1.5 | 19 | 2.5 | 11 | |||||||

| ASTM A351 CF8 | 0.08 | 2 | 1.5 | 19 | 0.5 | 10 | |||||||

| ASTM A351 CF8A | 0.08 | 2 | 1.5 | 19 | 0.5 | 10 | |||||||

| ASTM A351 CF8C | 0.08 | 2 | 1.5 | 20 | 0.5 | 11 | |||||||

| ASTM A351 CF8M | 0.08 | 1.5 | 1.5 | 19 | 2.5 | 11 | |||||||

| ASTM A351 CGMMN | 0.06 | 1 | 5 | 21.5 | 2.5 | 12.5 | 0.2 | 0.2 | 0.3 | ||||

| ASTM A351 CG8M | 0.08 | 1.5 | 1.5 | 20 | 3.5 | 11 | |||||||

| ASTM A351 CK20 | 0.8 | 1.75 | 1.5 | 25 | 0.5 | 21 | |||||||

| ASTM A351 CG-3M | 0.03 | 1.5 | 1.5 | 20 | 3.5 | 11 | |||||||

| ASTM A351 CE8MN | 0.08 | 0.8 | 1 | 24 | 3.75 | 10 | 0.2 | ||||||

| BS3100 302C25F | 0.12 | 1.5 | 2 | 19 | 1.5 | 8 | |||||||

| BS3100 302C35 | 0.3 | 2 | 2 | 20 | 8 | ||||||||

| BC3100 302C15 | 0.08 | 1.5 | 2 | 19.5 | 9.5 | ||||||||

| 10213 GX2CrNi 19-11 (1.4309 ) | 0.08 | 1.5 | 2 | 19.5 | 9.5 | ||||||||

| BS3100 304C15F | 0.08 | 1.5 | 2 | 19.5 | 2.5 | 9.5 | |||||||

| BS3100 304C12 | 0.03 | 1.5 | 2 | 19 | 2.5 | 9 | |||||||

| 10213 GX5CrNi 19-10 (1.4308 ) | 0.03 | 1.5 | 2 | 19 | 2.5 | 9 | |||||||

| BS3100 316C16 | 0.08 | 1.5 | 2 | 19 | 9 | ||||||||

| 10213 GX5Cr NiMo 19-11-2 | 0.08 | 1.5 | 2 | 19 | 9 | ||||||||

| BS3100 318C17 | 0.08 | 1.5 | 2 | 19 | 2.5 | 9 | |||||||

| NORTON NITRONIC 60 | 0.1 | 4 | 8 | 17 | 8.5 | ||||||||

| Super Austenitic | Nominal Composition | ||||||||||||

| Grade | C | Si | Mn | CR | Mo | Ni | Cu | Nb | V | Fe | W | Co | N |

| ASTM A351 CK3MCUN | 0.03 | 1 | 20 | 6.5 | 6.5 | 18.5 | 0.08 | 0.2 | |||||

| A341 CN7M | 0.07 | 1.5 | 20.5 | 2.5 | 2.5 | 29.5 | 3.5 | ||||||

At Shiney Steel, our mission is to manufacture and deliver products that meet your exact specifications. We go beyond just following details; we leverage our expertise and capabilities to ensure that every product we deliver is of the highest quality.

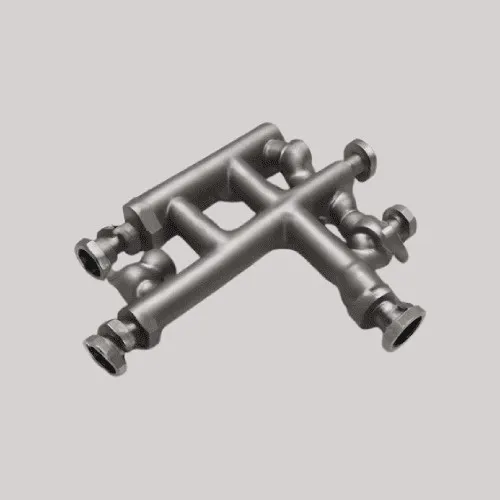

Valve and Pump Components

We specialize in producing valve and pump components for industries such as oil and gas, water treatment, and chemical processing. These parts are designed to endure high pressure, corrosion, and extreme temperatures.

Heavy Equipment Parts

Our steel castings are integral to the production of heavy equipment parts, including engine blocks, gears, transmission parts, and axle housings. These components are essential for industries like construction, mining, agriculture, and transportation, requiring exceptional strength, durability, wear resistance, and impact resistance.

Railway Parts

We provide essential steel castings for the railway industry, producing components such as bogie frames, couplings, brake discs, and vehicle accessories. These parts are built to be robust and reliable, withstanding continuous heavy use.

Energy and Power Generation Equipment

Our cast steel products play a vital role in the energy and power generation sectors, including turbine blades, casings, generator parts, and steam and gas turbine components. These parts demand superior heat resistance, strength, and precision.

Mining Machinery Parts

We manufacture steel castings for mining machinery, including parts like crusher plates, wear liners, and excavator components. These parts are built to handle abrasive materials, impact, and extreme operating conditions.

Auto Parts

Our steel castings are used in the automotive industry to produce critical components like engine blocks, cylinder heads, suspension parts, and transmission parts, which require high dimensional stability, strength, and the ability to withstand both thermal and mechanical stresses.

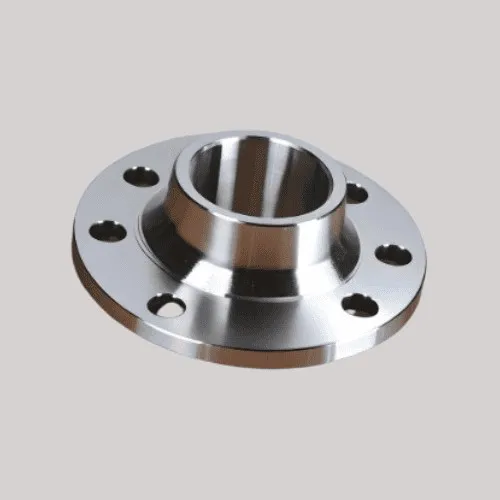

Pipe Fittings

We produce steel castings for pipe fittings such as flanges, elbows, tees, and reducers, serving industries like oil and gas, chemical processing, and water distribution.

Structural Hardware

We also manufacture structural hardware such as hinges, brackets, fasteners, and other components for buildings, bridges, and infrastructure projects, ensuring durability and compliance with strict construction requirements.