- Welcome to Hunan Shiney Steel Co., Ltd.

|

Composition |

Brass |

Bronze |

Copper |

|

Elements |

Primary: Copper, Zinc. |

Primary: Copper and Tin. |

Copper |

|

Corrosion Resistance |

Good Corrosion Resistance |

Excellent Corrosion Resistance |

Excellent Corrosion Resistance |

|

Weight |

8720 kg/cu.m |

7400 – 8900 kg/cu.m |

8930 kg/cu.m |

|

Durability |

Highly durable |

Highly durable |

Durable |

|

Machinability Level |

Lower |

Moderate |

High |

|

Weldability Level |

Good |

High |

High |

|

Electrical Conductivity Relative |

0.28 |

0.15 |

1 |

|

Thermal Conductivity |

64 BTU/hr-ft²-°F |

229 – 1440 BTU/hr-ft²-°F |

223 BTU/hr-ft²-°F |

|

Tensile Strength |

338 – 469 MPa |

350 – 635 MPa |

210 MPa |

|

Yield Strength |

95 – 124 MPa |

125 – 800 MPa |

33.3 MPa |

|

Melting Point |

927 °C |

913 °C |

1085 °C |

Alpha Brasses, a substitution solid solution of zinc in copper, contain 67-72% copper and 28-33% zinc. They are malleable and utilized in pressing, forging, and other related applications. Alpha brasses only have one phase and a face-centered cubic crystal structure. These brasses have a richer golden tone. It is robust, strong, and relatively difficult to machine. The best formability is achieved at 32% zinc. Corrosion-resistant can be worked cold.

Alpha-beta Brasses, also known as duplex brasses, are suitable for hot working, contain 55–65% copper and 35–45% zinc. They include both α and β’ phases. The β’-phase is ordered body-centered cubic, with zinc atoms in the centers of cubes, and is tougher and stronger than α. At 45% zinc, the alloy possesses its highest strength and because of the higher zinc content, these brasses are brighter than alpha brasses.

Beta Brasses contain 50–55% copper and 45–50% zinc. They are harder, stronger, and appropriate for casting. Because of the high zinc-low copper content, they are among the brightest and least golden of the typical brasses. Beta brasses are often used for higher–strength applications, such as valves, gears, and bearings. These brasses can only be worked hot.

Gamma Brasses contain 33–39% copper and 61–67% zinc. There are also Ag-Zn and Au-Zn gamma brasses, with Ag 30-50% and Au 41%, respectively. The gamma phase is an intermetallic compound with a cubic lattice structure, Cu5Zn8. Gamma brasses are typically used for specialized applications, including high-strength electrical contacts and fasteners.

|

PROPERTIES |

A260 |

A280 |

A360 |

A385 |

A464 |

|

Density (g/cm3) |

8.53 |

8.39 |

8.49 |

8.47 |

8.41 |

|

Hardness, Rockwell (F, B) |

54 F |

85 F |

78 B |

65 B |

55 B |

|

Yield Strength (MPa) |

75 |

145 |

124-310 |

138 |

172-455 |

|

Ultimate Tensile Strength (MPa) |

300 |

370 |

338-469 |

414 |

379-607 |

|

Elongation @ Break (%) |

68 |

45 |

53 |

30 |

50 |

|

Modulus of Elasticity (GPa) |

110 |

105 |

97 |

— |

100 |

|

Machinability (%) |

30 |

40 |

100 |

90 |

30 |

|

GRADES AND APPLICATIONS |

|

|

Alloy 260 - Cartridge Brass |

Another name for alloy 260 is cartridge brass. About 70% of this brass alloy is made of copper and 30% is zinc. Alloy 260 is easily cold-workable and has good hot formability. Among other things, it is utilised in fasteners, hardware, ammunition, and automobile components. |

|

Alloy 280 - Muntz Metal |

About 60% copper and 40% zinc make up Alloy 280. Muntz metal was frequently used as a less expensive substitute for the copper sheeting that was formerly applied to boat hulls to prevent the growth of marine life, such as barnacles. |

|

Alloy 360 - Free Machining Brass |

Alloy 360 comprises around 60% copper, 35.5% zinc, up to 3.7% lead, and 0.8% of iron. This is also an excellent choice for brazing and soldering applications. Designers and machinists it to create fittings, fasteners, valves & hardware components. |

|

Alloy 385 - Architectural Bronze |

The composition of alloy 385 is around 59% copper, 42% zinc, and up to 3.5% lead. This greatly improves its formability and machinability. This alloy is a fantastic architectural material for aluminium extrusions since it is simple to form. |

|

Alloy 464 - Naval Brass |

Naval brass, also known as alloy 464, is a corrosion-resistant metal composed of 40% zinc, 1% tin, and 59% copper. It is versatile in bending, soldering, welding, and cold and hot forming processes, making it ideal for various applications, including boat deck fixtures. |

Our goal at Shiney Steel is to provide high-quality products that meet your precise specifications and requirements. We don't just focus on the details; we bring in our expertise to deliver products that are not only functional but also superior in quality, ensuring timely delivery every time.

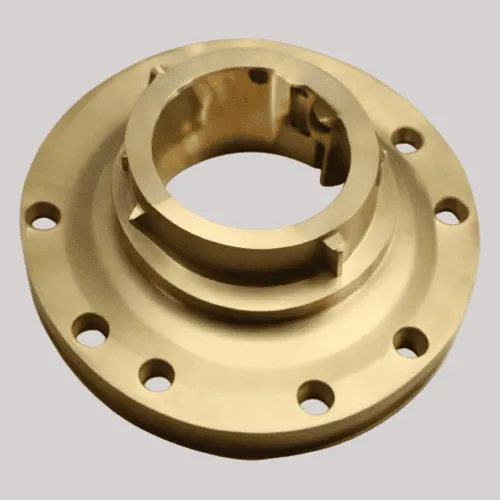

Pump Bodies

Leaded Gunmetal 85/5/5/5 (LG2) alloy is commonly used for producing pump bodies and bearings. This alloy offers moderate strength and excellent corrosion resistance to seawater, making it ideal for pump applications.

High-Load Bearings

Phosphor Bronze (PB1) castings are used for high-load bearings, particularly in applications requiring resistance to seawater, dilute acids, and boiler feed water. This alloy provides excellent bearing properties and corrosion resistance.

General Engineering Applications

Brass alloys like SCB3 are used in general-purpose castings for various engineering applications. SCB3 is chosen for its excellent machinability and versatility.

Ship Propellers

High-tensile brass castings made from HTB1 alloy are used to create ship propellers. This alloy delivers high strength and superior corrosion resistance to seawater, making it highly suitable for marine environments.

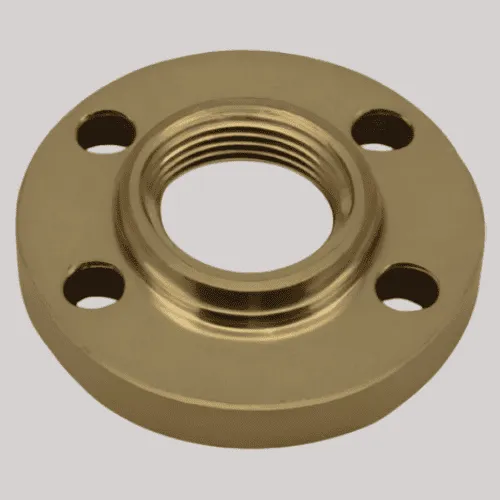

Valves and Plumbing Fittings

Brass castings are widely used in the production of valves, water pipes, and plumbing fittings such as those for air conditioners and radiators. Brass's strength, corrosion resistance, and ease of machining make it a preferred material for these applications.

Decorative Applications

Brass castings are used in various decorative items, including doorknobs, suspended-wire decorations, and other architectural elements, offering both durability and aesthetic appeal.

Automotive Components

Brass castings are utilized for automotive components where higher strength, corrosion resistance, and excellent machinability are required. The versatility of brass allows it to be used in a wide range of automotive applications, taking full advantage of the alloy's unique properties.