- Welcome to Hunan Shiney Steel Co., Ltd.

Range of Compositions for Typical Unalloyed Cast Irons (Values in Percent %)

|

Type of Iron |

Carbon |

Silicon |

Manganese |

Sulfur |

Phosphorus |

|

Gray |

2.5 – 4.0 |

1.0 – 3.0 |

0.2 – 1.0 |

0.02 – 0.25 |

0.02 – 1.0 |

|

Ductile |

3.0 – 4.0 |

1.8 – 2.8 |

0.1 – 1.0 |

0.01 – 0.03 |

0.01 – 0.1 |

|

Compacted Graphite |

2.5 – 4.0 |

1.0 – 3.0 |

0.2 – 1.0 |

0.01 – 0.03 |

0.01 – 0.1 |

|

Malleable (Cast White) |

2.0 – 2.9 |

0.9 – 1.9 |

0.15 – 1.2 |

0.02 – 0.2 |

0.02 – 0.2 |

|

White |

1.8 – 3.6 |

0.5 – 1.9 |

0.25 – 0.8 |

0.06 – 0.2 |

0.06 – 0.2 |

|

|

Brinell Hardness |

Tensile Strength |

Modulus of Elasticity |

% Elongation (in 50 mm) |

|

Gray iron class 25 |

187 |

29.9 ksi |

16.1 Msi |

- |

|

Gray iron class 40 |

235 |

41.9 ksi |

18.2 Msi |

- |

|

Ductile iron grade 60-40-18 |

130 – 170 |

60 ksi |

24.5 Msi |

- |

|

Ductile iron grade 129-90-02 |

240 – 300 |

120 ksi |

25.5 Msi |

- |

|

CGI grade 250 |

179 max |

36.2 ksi min |

- |

3 |

|

CGI grade 450 |

207 – 269 |

65.2 ksi min |

- |

1 |

Gray Iron

Gray iron is the most commonly used type of cast iron. It is known for its excellent strength, wear resistance, and heat conductivity. Its microstructure contains graphite, which gives it a characteristic gray appearance and contributes to its ability to dampen vibrations and resist wear.

Ductile Iron

Ductile iron, also known as nodular iron or spheroidal graphite iron, offers superior ductility, toughness, and tensile strength compared to gray iron. Its graphite forms nodules, enhancing the material's impact resistance and making it ideal for applications that require strength and durability, such as automotive and heavy-duty equipment parts.

White Iron

White iron derives its name from the bright white fracture surface it presents. It is characterized by exceptional hardness, abrasion resistance, and high strength due to its carbide microstructure. White iron is highly resistant to wear and is used in harsh applications where resistance to abrasion and high strength are critical, such as in crushers and grinding mills.

Malleable Iron

Malleable cast iron is produced by heat-treating white iron to break down the iron carbide into free graphite. This process makes the material more ductile and malleable, with excellent fracture toughness, especially at low temperatures. Malleable iron is used in applications that require both strength and the ability to absorb impact without cracking, such as in automotive components and industrial machinery.

Brake discs for the automotive industry

Pump housings and impellers for fluid handling applications

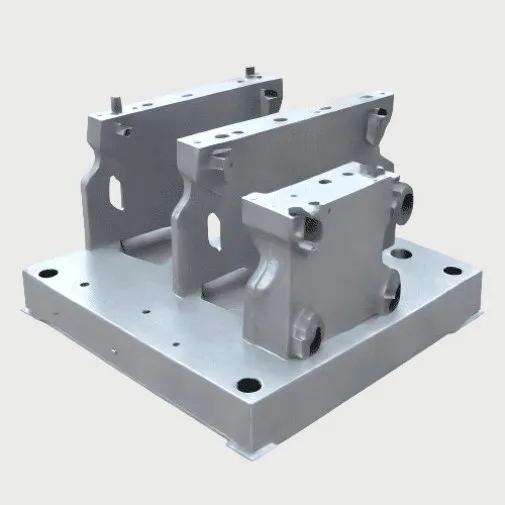

Machine frames and bases for industrial machinery

Manhole covers for infrastructure projects

Agricultural equipment components

Ductile Iron Castings

Gearboxes and transmission components for agricultural machinery

Gears, pulleys, and sprockets for industrial power transmission systems

Pipe fittings and connectors for plumbing and irrigation systems

Heavy-duty construction equipment components

White Iron Castings

Wear-resistant crusher plates for mining and quarrying industries

Chute liners and wear plates for material handling equipment

Dredge pump components for slurry pumping applications

Shredder parts for recycling machinery

Malleable Iron Castings

Electrical fittings and connectors

Pipe fittings for plumbing systems

Automotive component

Farm Equipment

Pipe Fittings

Mining Hardware