- Welcome to Hunan Shiney Steel Co., Ltd.

Here at Shiney Steel, our goal is to manufacture and deliver products as per the requirements considering their speciation given at the time of ordering. It’s not about the details alone but we also cooperate and put in our expertise and capabilities to ensure the most superior quality products are delivered to the customer.

|

Specification (AA) |

514 |

A413 |

A360 |

222 |

A380 |

A356 |

712 |

|

Tensile Strength (N/mm2) |

140-170 |

160-190 |

95-120 |

170 |

180 |

130-150 |

215 |

|

Elongation (%) |

3 |

5 |

05-Mar |

2 |

1.5 |

2 |

4 |

|

Brinell Hardness |

50-70 |

50-55 |

75-85 |

85 |

85 |

55-65 |

70 |

|

Density (g/cm3) |

2.65 |

2.65 |

2.68 |

2.7 |

2.79 |

2.68 |

2.81 |

|

Freezing range (deg C) |

642-580 |

575-565 |

575-550 |

620-550 |

580-520 |

615-550 |

615-570 |

|

Thermal Con @ 25degC (cal/cm2/cm/deg C) |

0.33 |

0.34 |

0.35 |

0.34 |

0.23 |

0.36 |

0.35 |

|

Electrical Con @ 20degC (% Copper Standard) |

31 |

37 |

38 |

39 |

24 |

39 |

35 |

|

Machinability |

Excellent |

Poor |

Fair |

Good |

Good |

Good |

Good |

|

Corrosion Resistance |

Excellent |

Excellent |

Good |

Good |

Fair |

Excellent |

Excellent |

|

Electro Plating Suitability |

F (2) |

F (1) |

F (1) |

F (1) |

Fair |

Fair |

Fair |

|

Non Spark |

No |

No |

No |

No |

No |

No |

No |

|

Casting Characteristics - Sand Casting |

Fair |

Excellent |

Good |

Good |

Fair |

Excellent |

Good |

|

Casting Characteristics - Gravity Die Casting |

Fair |

Excellent |

Good |

Good |

Fair |

Excellent |

Fair |

|

Casting Characteristics - High Pressure Die Casting |

Fair |

Good |

* |

* |

Excellent |

Good |

Fair |

1 - These alloys, containing Silicon,require a modification treatment for good adhesion

2 - Can be plated, but not recommend

|

Grade |

Application |

|

A05140 |

Commonly used for casting applications that require good corrosion resistance and high strength, making it suitable for marine components, pump housings, and valve bodies. |

|

A04013 |

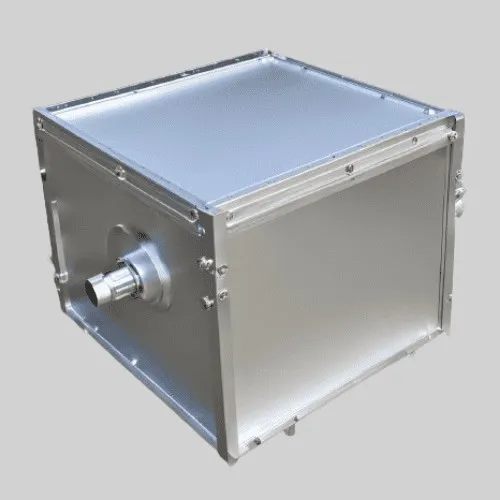

Known for its excellent castability and weldability, making it ideal for creating intricate cast components such as automotive parts, heat exchangers, and electrical enclosures. |

|

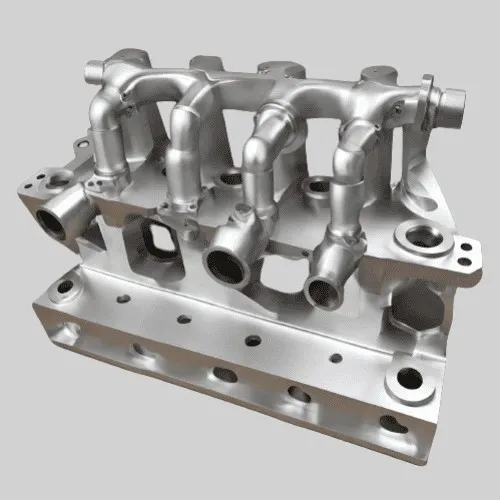

A03600 |

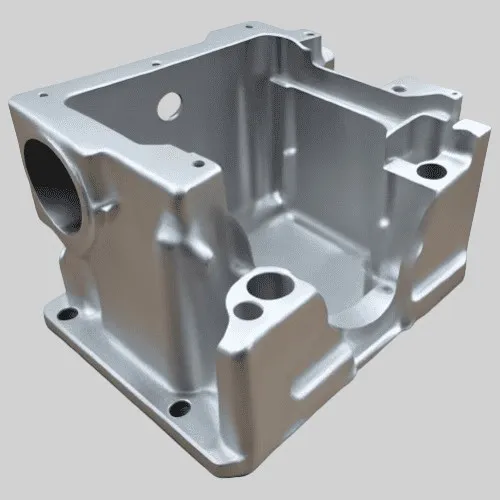

Utilized in casting processes where high machinability and good corrosion resistance are essential, making it suitable for producing components like hydraulic manifolds, instrumentation components, and pressure vessels. |

|

A03550 |

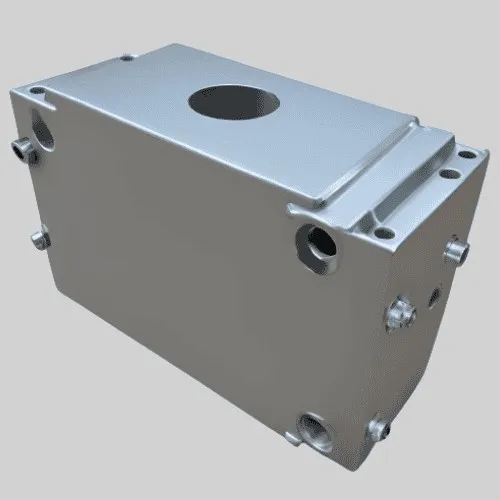

Favored for its combination of high strength and thermal conductivity, making it suitable for casting applications such as heat sinks, motor housings, and automotive transmission components. |

|

A03800 |

Used in casting applications that require a good balance of strength, ductility, and corrosion resistance, making it suitable for manufacturing components such as aircraft parts, pump bodies, and hydraulic cylinders. |

|

A03560 |

Known for its excellent castability and weldability, making it a popular choice for casting components such as automotive engine blocks, cylinder heads, and structural parts in the aerospace industry. |

|

A03280 |

Used for casting applications where high strength and wear resistance are crucial, making it suitable for producing components like gears, bearing housings, and machine tool parts. |

|

A03100 |

Known for its high thermal conductivity and good corrosion resistance, making it suitable for casting applications that require heat dissipation, such as heat exchangers, electronic enclosures, and lighting fixtures. |

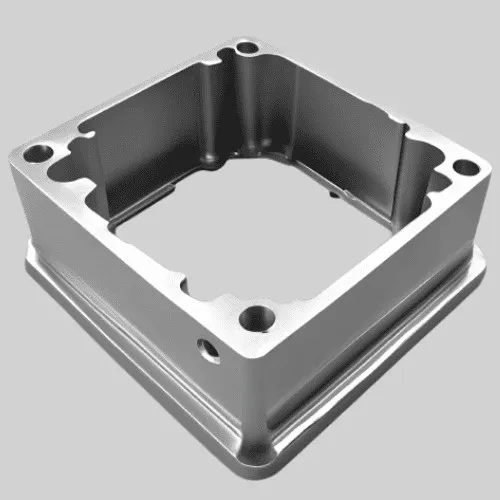

1. High Pressure Die Casting

High-pressure aluminum die casting is a precision manufacturing process where molten aluminum is injected under high pressure into a steel mold, known as a die, to form products. This method is ideal for producing thin-walled aluminum components in high volumes. High-pressure die casting is known for producing parts with minimal machining and finishing required, making it an efficient choice for precision parts.

2. Low Pressure Die Casting

In low pressure die casting, molten aluminum is transferred from an airtight furnace into a metallic tool through a rising tube under low pressure. This method is often used when a small production volume is required or when heat treatment is needed to enhance the material's mechanical properties. It is typically used for producing thicker aluminum products, offering the same surface finish and tolerances as gravity die casting, but at a higher tooling cost.

3. Gravity Die Casting

Gravity die casting involves the pouring of molten aluminum into molds or cores made from steel or other metals. This method often involves the application of a vacuum, and it produces castings stronger than those made by die casting or sand casting. Gravity die casting is especially useful for parts requiring permanent cores that are difficult to remove. This process is also called aluminum gravity casting, commonly used in China.

4. Sand Casting

Sand casting is the most versatile method for producing aluminum products, often chosen for intricate designs or large castings. It begins with a pattern of the finished part, which is pressed into a fine sand mixture to form the mold. The pattern is slightly larger than the final part to accommodate aluminum shrinkage during solidification and cooling. While sand casting is slower than die or permanent mold casting, it is generally more economical for small quantities or complex, large designs.