- Welcome to Hunan Shiney Steel Co., Ltd.

The crankshaft is one of the most critical components in automotive engines, converting reciprocating motion from pistons into rotational motion to drive the wheels. Given its demanding operational environment—subjected to dynamic stresses, vibrations, and continuous cyclic loading—optimizing crankshaft durability and fatigue performance is crucial. Two primary manufacturing processes for automotive crankshafts are casting and forging. Each method significantly influences the component's microstructure, mechanical properties, and ultimately, its fatigue resistance. This article examines these processes, emphasizing fatigue performance to guide optimal selection.

Overview of Casting and Forging Processes

Casting

Casting involves pouring molten metal into a mold, allowing it to solidify into the desired shape. Typical casting methods for crankshafts include:

l Sand Casting: Cost-effective, flexible in shapes but prone to porosity and inclusions.

l Ductile Iron Casting: Employs spheroidal graphite iron, offering improved mechanical properties and castability.

l Investment Casting: More precise, used primarily for high-performance or specialty crankshafts.

Forging

Forging utilizes mechanical deformation (hammering or pressing) to shape heated solid metal into a die. Forged crankshafts commonly employ closed-die forging, characterized by:

l Superior grain flow alignment

l Enhanced strength and ductility

l Reduced internal defects

Fatigue Performance: Metallurgical Perspectives

Fatigue failure, resulting from cyclic stresses, initiates from microstructural imperfections or stress concentrators. A crankshaft experiences bending, torsion, and complex stress cycles. Thus, fatigue resistance is a paramount consideration.

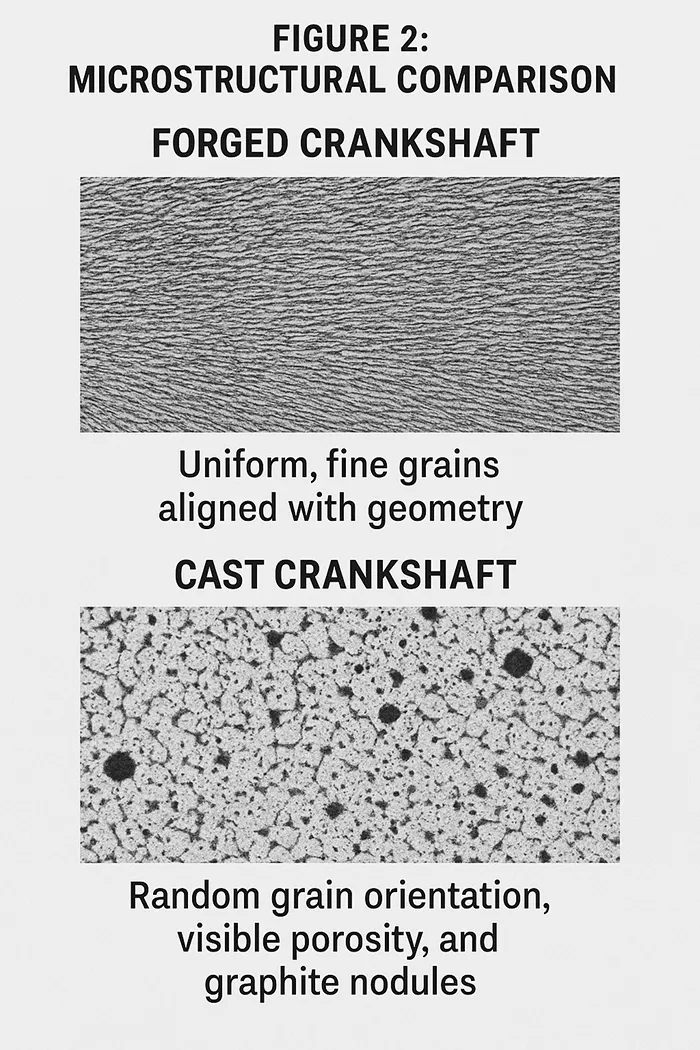

Casting typically results in a microstructure featuring random grain orientation, porosity, and inclusions, creating initiation points for fatigue cracks. By contrast, Forging enhances fatigue resistance due to controlled grain flow, refined grain structure, and reduction in internal defects.

Fatigue Testing and Data Analysis

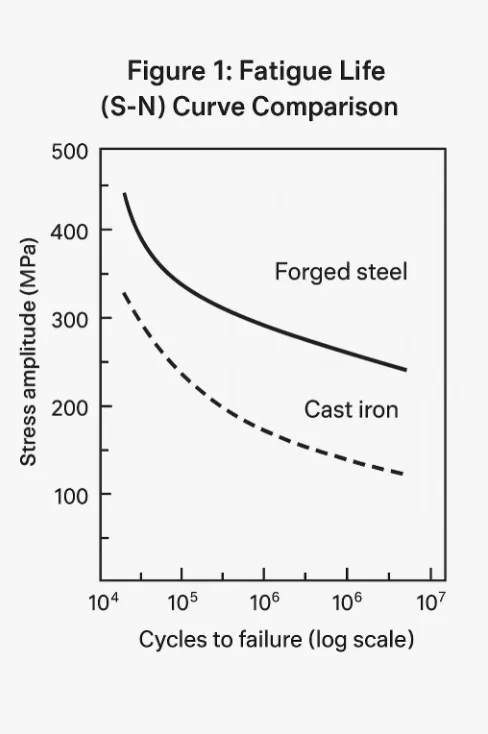

Fatigue tests comparing cast and forged crankshafts show clear distinctions in their performance, generally represented using S-N (stress-life) curves.

Typical S-N Curves (Illustrative)

l Forged Crankshafts: Higher fatigue limit (~400 MPa for forged steel), indicating prolonged life under cyclic loading.

l Cast Crankshafts: Lower fatigue limit (~250 MPa for cast ductile iron), limiting endurance under high cycle stresses.

Case Study: Comparative Performance in Automotive Engines

Forged Steel Crankshafts

Commonly used in performance or heavy-duty engines due to:

l High fatigue strength

l Longer service life under aggressive conditions

l Resistance to crack initiation and propagation

For example, diesel engines in trucks and high-performance sports cars typically employ forged crankshafts to withstand higher combustion pressures and dynamic loads.

Cast Iron (Ductile Iron) Crankshafts

Dominant in passenger vehicles due to cost-effectiveness:

l Acceptable fatigue performance for moderate stresses

l Economically viable for mass production

However, cast crankshafts exhibit higher susceptibility to fatigue cracking under prolonged, severe loading, necessitating careful design and quality control.

Microstructural Factors Influencing Fatigue Performance

Casting Defects

l Porosity: Gas bubbles trapped during solidification create internal voids.

l Inclusions: Non-metallic impurities, acting as stress concentrators.

l Graphite Morphology (in ductile iron): Graphite nodules, beneficial over flaky graphite, still influence fatigue crack initiation.

Forging Benefits

l Directional Grain Flow: Aligns grain boundaries along the stress paths, reducing stress concentrations.

l Refined Grain Size: Achieved through controlled deformation, improves fatigue crack initiation resistance.

Economic Analysis and Mass Production Feasibility

Cost Implications

l Casting: Lower initial tooling costs, suitable for high-volume production.

l Forging: Higher tooling and production costs but cost-effective in long-term, high-performance applications due to reduced failure rates.

Manufacturers often weigh upfront costs against expected component life, service conditions, and warranty liabilities.

Optimizing Manufacturing for Enhanced Fatigue Life

Advanced Casting Techniques

l Chill Casting: Rapid solidification to reduce grain size and minimize defects.

l Vacuum Casting: Significantly reduces porosity and inclusions.

Forging Innovations

l Warm Forging: Offers finer grain structures, improving fatigue performance without excessive tooling wear.

l Incremental Forging: Enhances grain alignment precisely along stress paths.

Non-destructive Testing (NDT) and Quality Assurance

Ensuring fatigue performance requires rigorous inspection:

l Ultrasonic Testing (UT): Detects internal voids or inclusions.

l Magnetic Particle Inspection (MPI): Reveals surface or near-surface cracks.

l Computed Tomography (CT): Advanced inspection to precisely map internal defects.

Future Trends: Hybrid Approaches and Material Innovation

Emerging trends in crankshaft manufacturing include:

l Hybrid Structures: Combining cast and forged sections to optimize performance-cost balance.

l Material Advancements: Utilizing austempered ductile iron (ADI) or microalloyed steels to bridge gaps between traditional casting and forging strengths.

Conclusion

In automotive crankshaft manufacturing, the choice between casting and forging significantly impacts fatigue performance and reliability. Forged crankshafts deliver superior fatigue life due to their controlled microstructures, making them indispensable in high-performance or heavy-duty applications. Conversely, cast crankshafts remain economically attractive for standard consumer vehicles, albeit with lower fatigue limits.

Manufacturers must consider application-specific demands, economic viability, and technological advancements to select the optimal process. Ongoing improvements in both casting and forging technologies continue to enhance the fatigue performance of crankshafts, ensuring reliable and efficient automotive engines well into the future.